Introduction

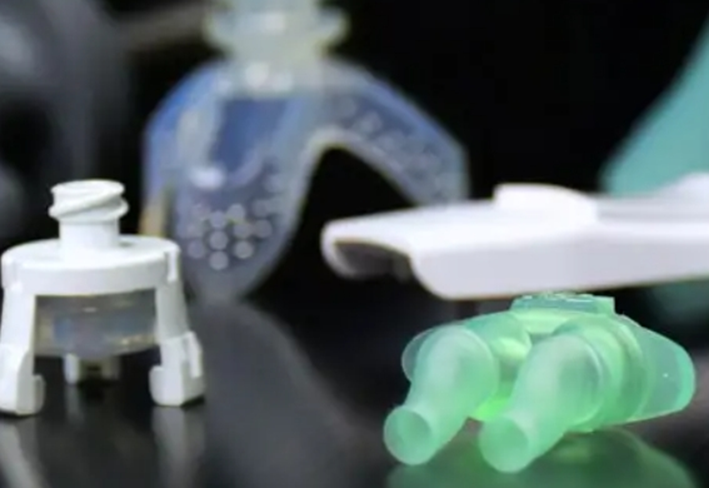

Hordrt’s silicone compression moulding services offer a highly efficient and cost-effective method for producing a wide range of elastomer silicone rubber molded parts. This process is known for its numerous advantages, making it a preferred choice for manufacturers seeking reliable and economical solutions. Below, the many benefits of silicone compression moulding provided by Hordrt are explored.

Minimal Material Waste

One of the significant advantages of Hordrt’s silicone compression moulding services is the minimal loss of raw material. Typically, only 2% to 5% of the product’s material is wasted during the moulding process, which ensures that resources are used efficiently and reduces overall production costs.

Stable Mechanical Properties

The end products produced through Hordrt’s silicone compression moulding have low internal stress and minimal warping deformation. This stability in mechanical properties ensures that the parts are durable and perform reliably in their intended applications.

Low Maintenance Costs

Another advantage of choosing Hordrt for silicone compression moulding is the extended life of the mold cavity, coupled with low maintenance costs. The simplicity of the mold structure not only reduces wear and tear but also keeps the mold maintenance expenses at a minimum, making it a cost-effective option for long-term production.

Cost-Effective Moulding Equipment

Hordrt’s silicone compression moulding process is characterized by the use of less expensive moulding equipment. The simpler mold structure allows for the production of multiple cavities at a lower cost, significantly reducing the overall manufacturing expenses when compared to other methods like injection molding.

Suitable for Large Flat Products

Silicone compression moulding by Hordrt is particularly suitable for producing large flat products. The size of the products that can be molded is determined by the mold clamping force of the pressing machine and the size of the mold plate, making it ideal for producing sizable components.

Batch Production at Low Cost

For manufacturers requiring parts in batches, Hordrt’s silicone compression moulding services offer a cost-effective solution. The ability to place molds with a high number of cavities on a single plate further enhances productivity, allowing for efficient large-scale production at a relatively low price.

Conclusion

Hordrt‘s silicone compression moulding services provide a wide array of advantages, including minimal material waste, stable mechanical properties, low maintenance costs, and cost-effective equipment. The process is ideal for producing large flat products and is especially suitable for batch production, offering manufacturers an economical and efficient solution. With Hordrt’s expertise, companies can benefit from the many advantages of silicone compression moulding to achieve high-quality products at a competitive price.